VEICHI SD700 series servo drives are high performance, high reliability, high quality, and cost-effective products to meet a variety of industrial environments and critical system applications and achieve the perfect combination of servo and program.

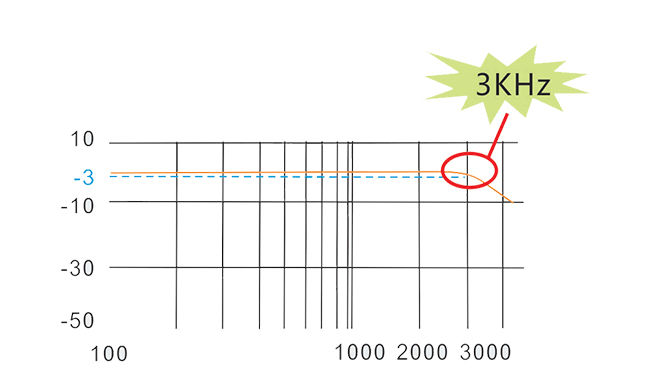

1. The speed loop response bandwidth can reach 3kHz.

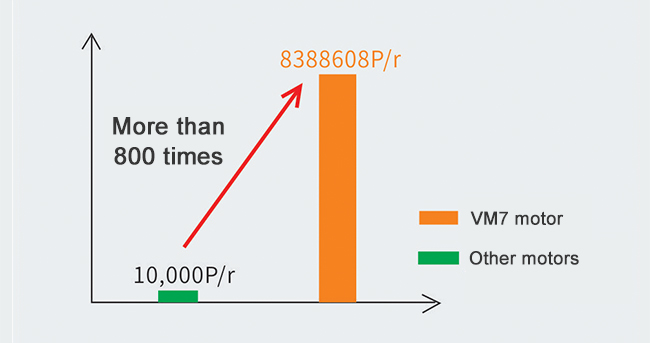

2. Using a 23-Bit absolute encoder, the communication speed can reach 2.5Mpps.

3. Bandwidth setting, automatically complete PID loop gain calculation.

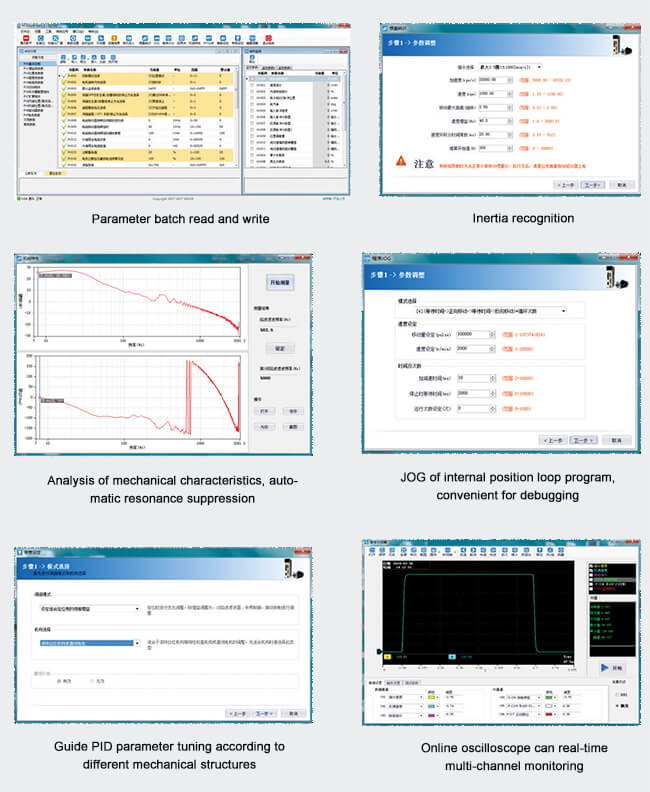

4. Powerful PC software, multi-channel monitoring, easy to use.

5. Automatically complete inertia identification, loop gain, friction compensation, and other parameter settings.

6. Support multi-stage vibration control function, effectively limit resonance.

7. Robust control ensures smooth operation of loads with inertia within 30 times.

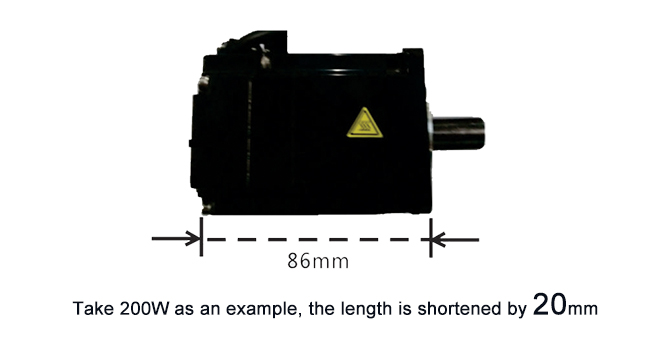

8. New structural appearance design, compact and space-saving.

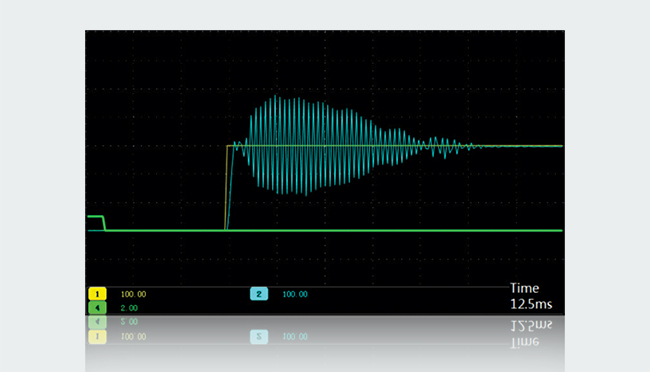

Through the unique current loop algorithm, the bandwidth of the speed loop is effectively increased, and the setting time is greatly shortened. The fastest setting time can reach 1ms, which improves production efficiency.

1. Standard 23-Bit multi-turn absolute encoder, single-turn up to 8388608 pulses, communication speed up to 2.5Mpps.

2. The positioning is more accurate, the low speed is more stable, and the power-off position is not lost.

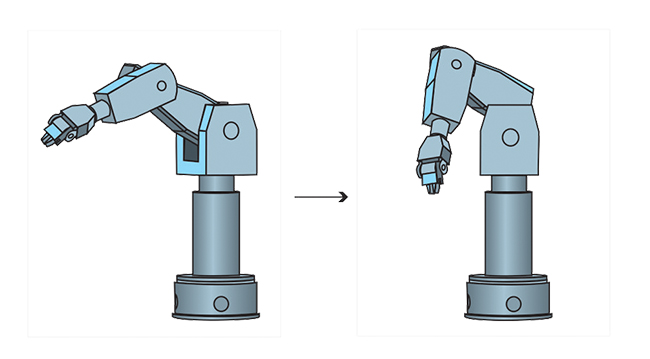

1. The new control theory algorithm is adopted to realize that even if the load moment of inertia changes within 30 times during the movement, there is no need to set the slave parameters to ensure smooth operation.

2. It can be used after installation. This function is widely used in manipulators.

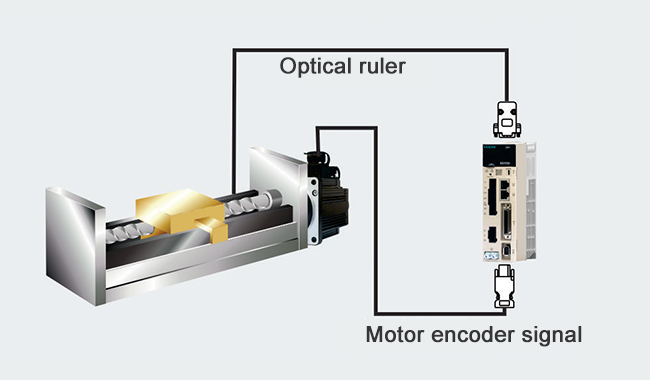

The fully closed-loop mode supports an external second encoder or grating ruler, which reduces errors caused by the mechanical transmission gap and improves positioning accuracy. All models are equipped with this function.

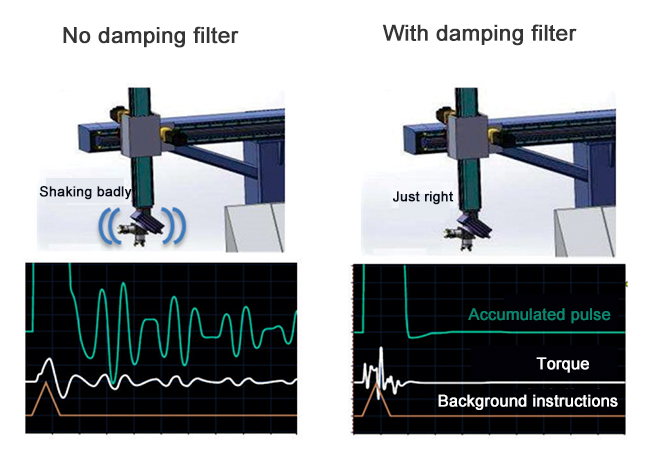

The damping filter can be set through the host computer software, which can effectively eliminate the inherent vibration frequency, greatly reduce the vibration (shaking) of the shaft when stopping, and can effectively suppress the vibration of 0~100Hz frequency. This function is commonly used to eliminate injection molding robots and stackers The end shakes when stopped.

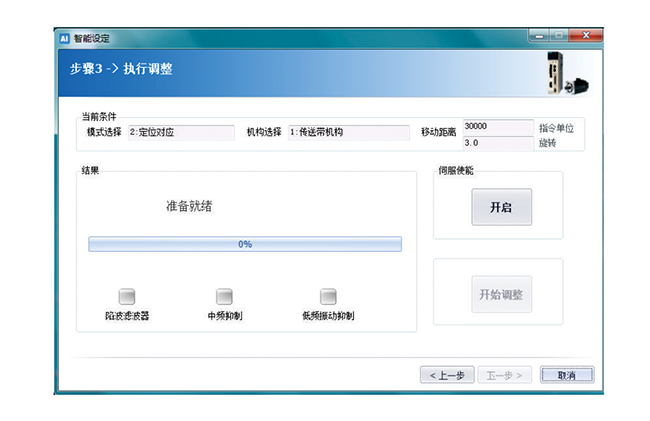

1. There is no need to perform complex vibration frequency measurement and analysis, and the notch filter can be quickly searched and automatically set during the parameter tuning process through the single parameter adjustment function of the host computer.

2. Simple and easy to use, the fastest does not exceed 70ms. It can greatly reduce the noise and vibration caused by the mechanical resonance of the equipment, to achieve a faster response action. This function is widely used in machine tools.

Automatic gain adjustment, guided setting mode, the sequential setting can complete the setting of servo gain, simple and easy to use. Provides more adjustment modes, which can be adjusted according to different mechanical structure and process characteristics, so that the machine can reach a suitable state.

Support RS-485, EtherCAT, CANopen, MECHA-METROLINK, MECHATROLINK, and other mainstream buses.

It adopts a 10-stage rotor and 12-slot spindle design. Through a special magnetic circuit design, the cogging effect is effectively suppressed and torque ripple is greatly reduced, thereby ensuring that the motor runs more smoothly at a constant speed and low speed.

1. No need to install and debug software.

2. USB communication between the drive and the computer, easy to use.

Applications:Electronic manufacturing equipment, numerical control equipment, packaging machinery, printing machinery, textile machinery, plastic machinery and glass equipment, testing equipment, etc.